In this article we’ll look at some quick tips your technicians can use to get the most out of your wheel alignment equipment.

Accurate wheel alignment is essential for the smooth and safe operation of any vehicle. Misaligned wheels can cause a number of issues, including uneven tyre wear, reduced fuel efficiency, and poor handling. That's why it's crucial to use high-quality equipment when performing wheel alignments.

John Bean is a leading manufacturer of wheel alignment equipment, and our products are renowned for their accuracy and reliability. In this article, we'll take a closer look at some of the best practices for using John Bean wheel alignment equipment systems to ensure your wheel alignment calibrations are perfect every time.

Before you get started:

It is important to perform a vehicle inspection prior to performing a wheel alignment check:

- Verify the tyres' specifications, including their size, tread depth, pressure

- Examine the tyres for damage such as cuts, bulges, or other faults

- Examine the tyre wear pattern for any abnormalities. Since the tread should normally be worn evenly all the way around the tyre, any uneven wear may be caused by misalignment

- Check that wheel rims are not damaged

- Verify the ride height is accurate, to the manufacturer's specification

- Check that no undue play exists in the steering or suspension systems including bearings and bushes

- Check that the steering and suspension systems, including the bearings and bushes, don't have any excessive play

Before beginning the wheel alignment, you should take the vehicle for a test drive. If at all possible, choose a flat, quiet road and look out for any of the following potential problems:

- Steering pull to the left or right

- Steering wheel position

- Steering self-centring after a turn

- Abnormal steering or suspension noises

- Steering effort

- Steering play

- Wheel balance

John Bean's wheel alignment equipment is designed to work with a wide range of vehicles, but it's essential to follow the manufacturer's guidelines for each specific make and model.

This includes selecting the appropriate targets, using the correct procedures for adjusting camber, caster, and toe, and ensuring that all measurements are within the recommended tolerances.

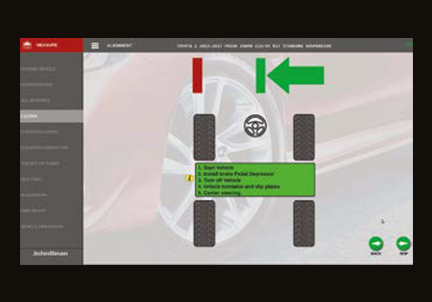

1. Alignment turn plates must be able to freely move. They must be able to move not only in a circular motion but also back and forth and side to side. This is particularly crucial for precise caster measurements. Conventional MOT-type turning plates are not suitable for wheel alignment which only rotate about a centre pin.

2. A rear sliding plate must be used, if you adjust rear toe/camber. It removes all the stress from the suspension and avoids flexing the tyre, which generates inaccurate readings. The plate should move freely without sticking, although turn plates can also be used to support rear wheels.

3. Premature wear and alignment precision are both impacted by routine lubrication that is neglected. The cameras' pins need to be lightly oiled if they stick otherwise they'll give inaccurate. Remember to follow the manufacturer's maintenance recommendations and avoid using grease because it tends to attract grit.

4. In addition to the pins already mentioned, conduct regular inspections to make sure that all other necessary components are functional and in good condition.

5. Where battery packs are fitted in the heads, ensure that they are charged adequately before starting a procedure. Some PC-based aligners have battery diagnostic facilities and will display battery status as well as ability to set low-charge warnings.

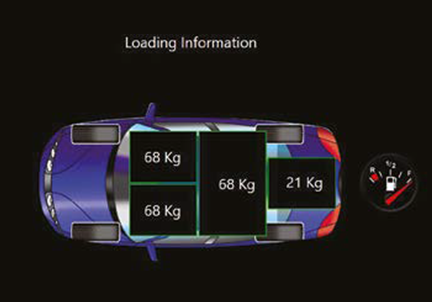

6. All OEMs recommend that the suspension is loaded, i.e all wheels support the vehicle's weight. Some of them have additional and more complex requirements, such as placing weights within the vehicle and even that the fuel tank is full. Do not ignore these instructions.

7. On some vehicles, the suspension must be put into wheel alignment mode to ensure a successful result. This can only be set via a diagnostic scan tool. A steering angle sensor reset, or ADAS calibration might also be required afterwards.

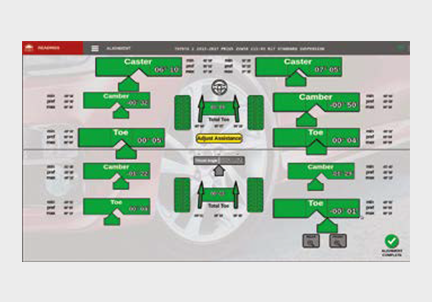

8. Many technicians skip the simple process of rocking the steering from side-to-side to measure the caster because it is not adjustable on many cars. Yet, as the caster can be an indication of bent suspension components, it is worth checking to see if further repairs are required to restore the correct geometry.

9. Take a closer look at the readings and do not think the job is complete when the setting turns green on your screen. This is because the geometry may remain imbalanced, which could manifest itself as poor handling.

10. A good quality and well-installed alignment lift provides not only a level surface but also possesses recesses for front turn-plates and rear sliding plates. The main advantage is that the vehicle’s suspension is not disturbed and, therefore, will not require to be settled in order for you to gain accurate readings quickly.

Bonus tip:

One last recommendation is to make sure you follow the EZ-Toe procedure before completing the wheel alignment.

EZ-Toe is an adjustment assistant that guides the technician through the toe adjustment process without the need to lock the steering wheel.

Many technicians will skip the EZ-Toe procedure and experience a crooked steering wheel after the alignment is complete. Check out this video which shows you how to make the most of the EZ Toe feature on your John Bean Alignment system.

Applies to: John Bean Alignment Series including the: V2000, V1200, V2200, V2260, V2280, V2300, V2400, V3400

By following these best practices, you can maximise the performance of your equipment and ensure that your customers' vehicles are always operating safely and smoothly.

Incorporate wheel alignment into your routine

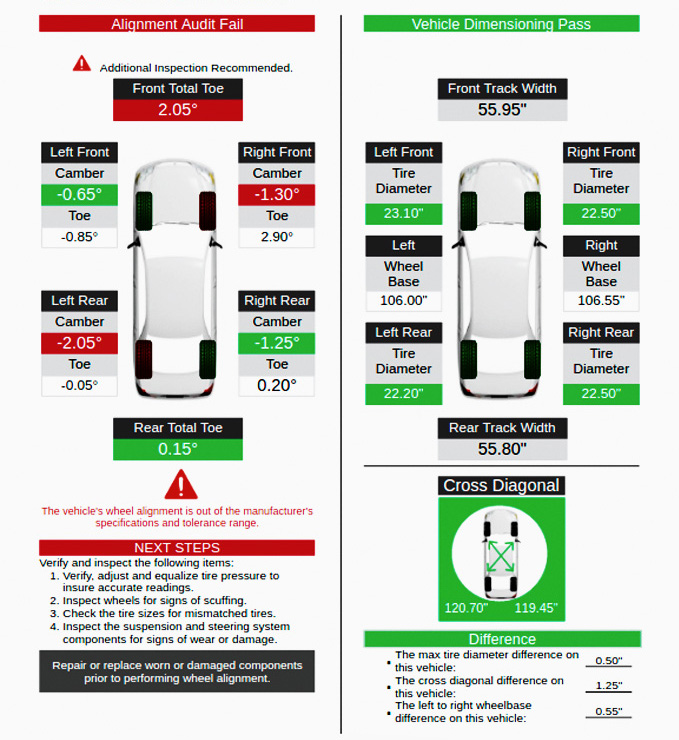

Making an interim alignment check-up part of your routine rather than an additional service (charge) takes just a few minutes to run and costs nothing to your customer. You can present them with the results and advise of corrective measures that should be done to prevent damage to components down the line.

By physically showing the issue to the customer, as well as the advantages of having the alignment fixed will help the customer understand the need is greater to apply preventative maintenance rather than pay down the line fixing other issues. This is a value-added upsell to increase your revenue with relatively little additional work for your technicians

For vehicles that do not require corrective action, it’s still a great value add to your service as those positive results give customers added peace of mind. Likewise, those vehicles requiring corrective measures it is a value-added upsell t your services which again should give your customers peace of mind afterwards that you are assisting with preventative maintenance to save them money in the long run.

How wheel alignment can really impact your bottom line

The state of UK roads is at an all-time low, potholes are the number one cause of suspension defects, and your customers are 1.5 times more likely to breakdown after hitting a pothole today than they were more than ten years ago! There is a major need for regular interim alignment check-ups, and there are customers rolling past your doors every day in need of your help!

Discover how adding wheel alignment to your daily routine give your customers added peace of mind and easily earn you hundreds of pounds in extra revenue a day!

©2024 Snap-on Incorporated. All rights reserved.