Emissions Testing

How technicians can leverage the OBD Health-Check function on the SUN DGA6000 LINK to increase revenue.

In this article, we’ll take a closer look at the OBD health-check function on the Sun DGA6000 LINK and how technicians can use it to generate additional revenue by identifying and recommending repairs to your customers

Independent garages are continually seeking ways to enhance their productivity and increase revenue. One valuable tool that can significantly assist technicians to achieve these goals is the On-Board Diagnostic (OBD) health-check function found within the SUN DGA6000 LINK. This advanced emissions diagnostic system conducts a comprehensive assessment of a vehicle's emissions system automatically during the emissions testing process.

Understanding the OBD Health-Check Function

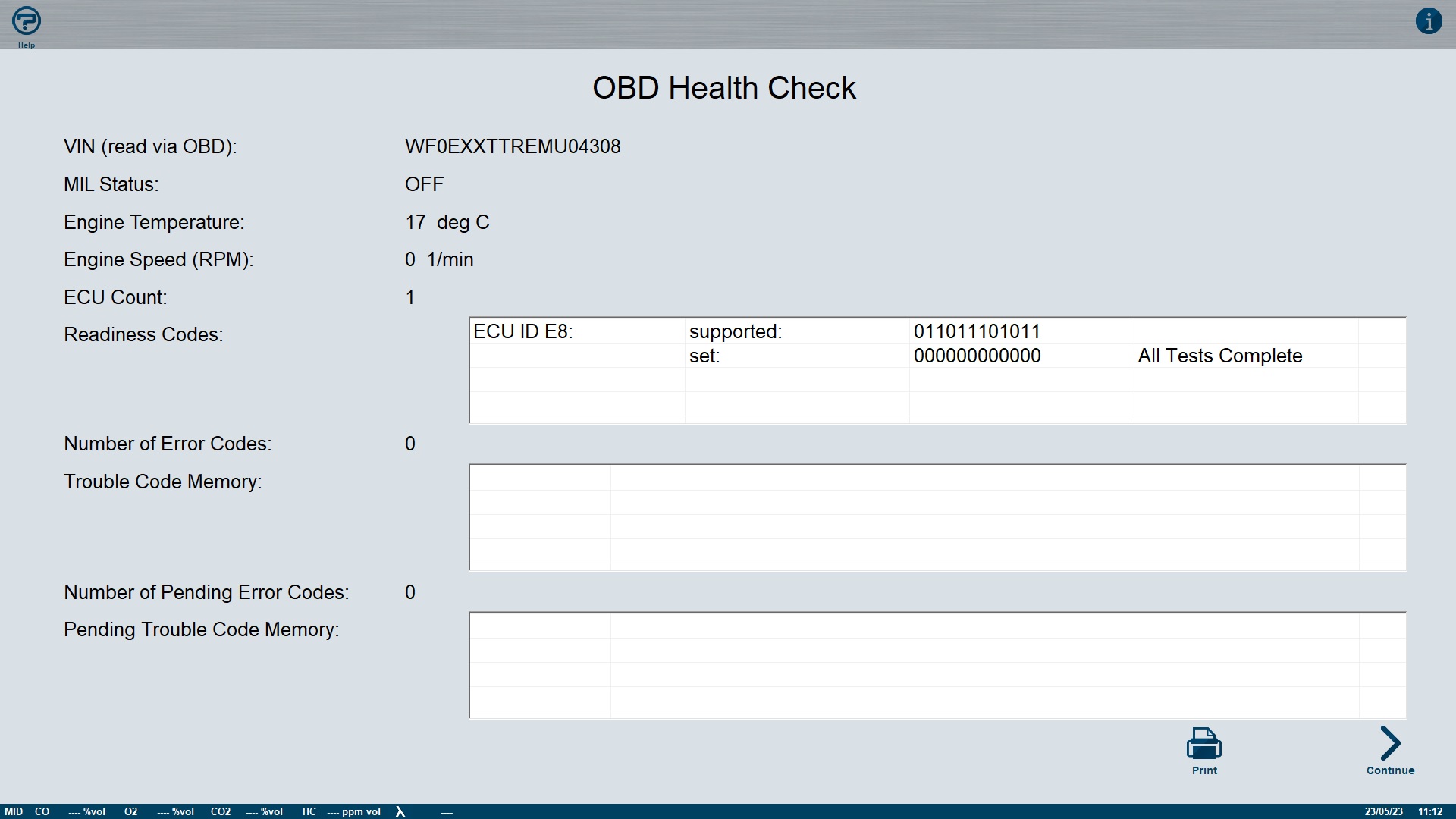

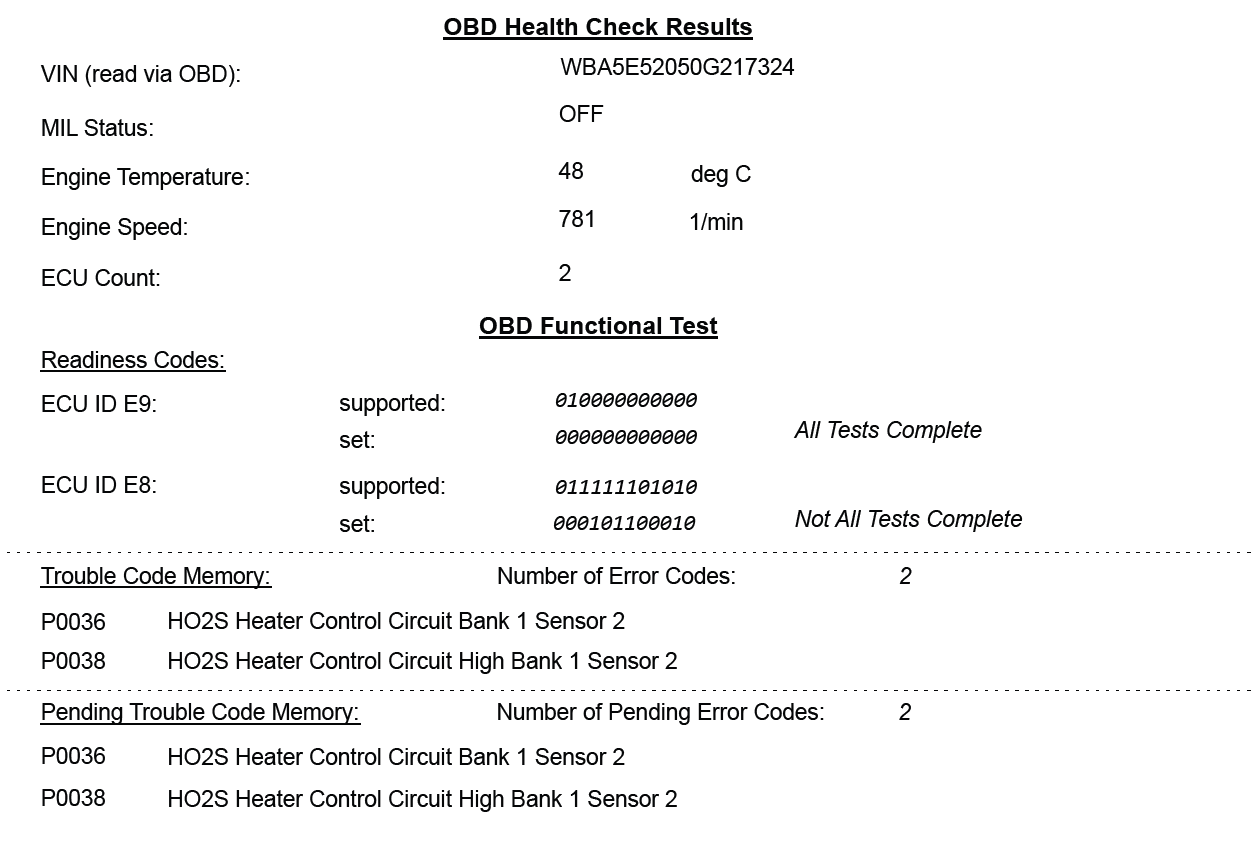

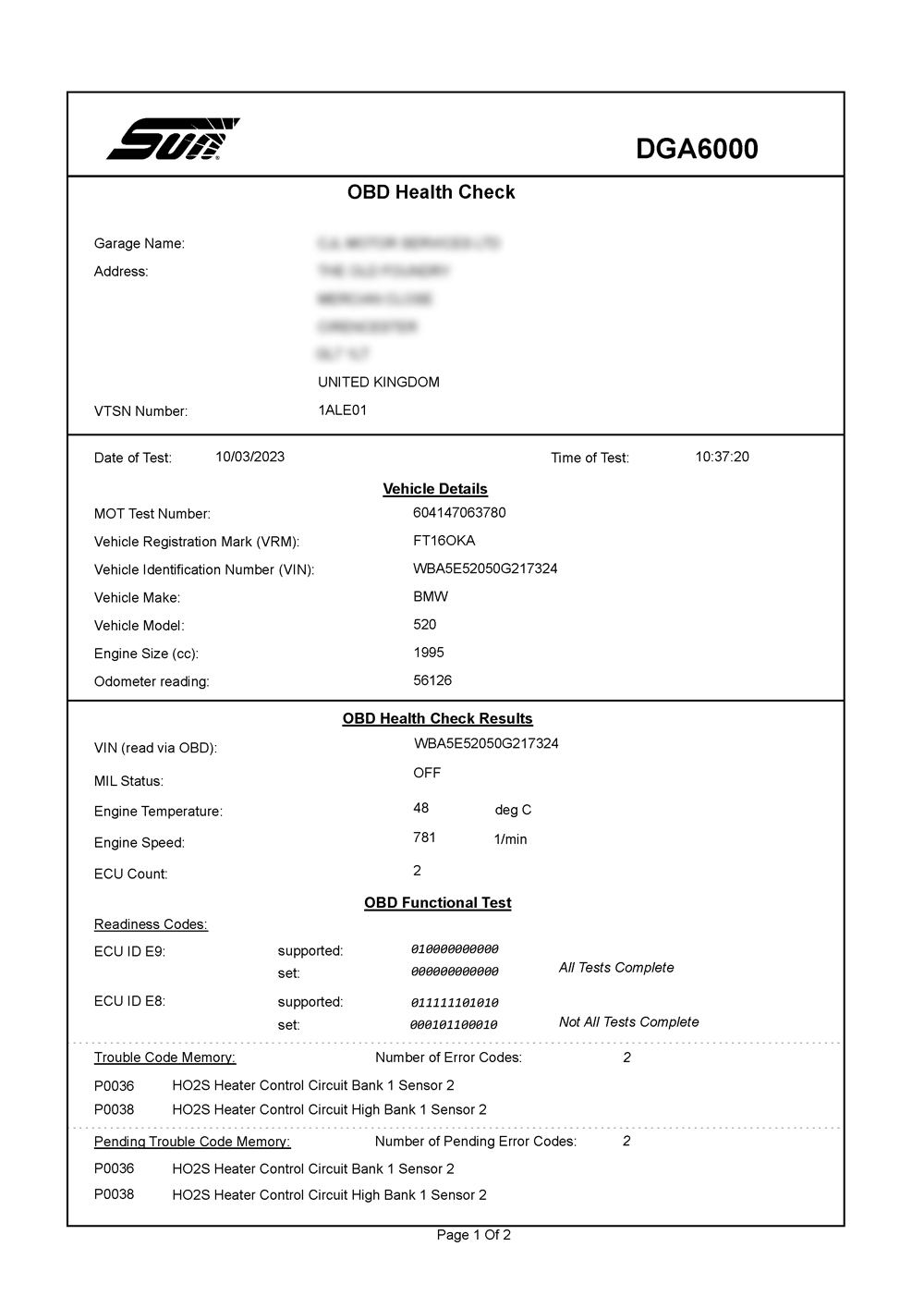

The OBD health check function on the SUN DGA6000 LINK is a powerful feature designed to provide technicians with a detailed report on the condition of a vehicle's emissions system automatically during the emissions testing procedure. The system retrieves from the vehicle's ECU including error codes, pending codes and MIL status related to the vehicle’s emissions system. This data can then be reviewed to identify potential problems, monitor system performance, and assess the overall health of the emissions system.

The system will flag fault codes and pending codes automatically during the emissions testing process and summarise all the data in an OBD health check report at the end of the emissions testing procedure. This report can be printed out and presented to the customer or sent as a PDF via email to present the findings of the OBD health check and provide advice and corrective maintenance of the identified faults.

Independent garages can leverage OBD Health-check reports expanding revenue opportunities every single day. This can be achieved in several ways including:

On-Demand Scanning: Vehicle owners often seek professional assistance when their vehicle's check engine light illuminates. If this is illuminated during the MOT test, this will result in an emissions test failure. By utilising the OBD health check function, technicians can perform an immediate scan of the emissions system to identify the underlying issue that is causing the check engine light to illuminate. The fix for the issue can then be investigated further and charged separately from the MOT test, giving workshops an opportunity to capitalise on the urgency of the situation and carry out repair work to fix the issue and retest the vehicle.

Advance Diagnostic Testing: The Sun DGA6000 LINK’s OBD health-check identifies emissions trouble codes as well as pending codes and when required, technicians can present these results to the customer with a recommendation of further investigation in the form of a complete diagnostic scan. For example, by charging a reasonable fee for performing these scans, with an advanced diagnostics tool like the Snap-on ZEUS, TRITON and APOLLO. These Snap-on Diagnostic Tools include Fast-Track ID which can quickly identify any problems with the vehicle and provide recommended repairs, saving technicians time and improving the accuracy of their work and enabling them to provide accurate estimates and recommendations to customers for repairs or maintenance, establishing trust and increasing customer satisfaction.

Preventive Maintenance: OBD health-checks can be utilised as a part of a proactive maintenance strategy. For your returning customers, the Sun DGA6000 LINK will automatically scan and store emissions systems data allowing technicians to gather valuable from the emissions system over time. This can be used to identify potential emissions issues before they become major problems. By flagging pending trouble codes, technicians can identify and offer preventive repairs or maintenance services to customers and help them to avoid costly breakdowns and extend the lifespan of the vehicle.

Conclusion

By leveraging the OBD health check function on the Sun DGA 6000 LINK, vehicle technicians can enhance their productivity and increase their revenue. Offering comprehensive diagnostic services, advising customers on proactive maintenance and targeted system assessments allows technicians to cater to a wide range of customer needs.

Moreover, the ability to provide on-demand scanning services and data-driven maintenance further expands revenue opportunities. Embracing the power of this advanced diagnostic gas analyser positions technicians as trusted experts, fostering customer loyalty and driving long-term business growth in the automotive industry.

Sun Emissions Systems Routine Maintenance

To ensure accurate emissions testing using the Sun DGA Series of emissions analysers, it is essential to regularly check, maintain, and replace the following system components to ensure accurate measurements:

O2 Cell – Degrades over time and can eventually lead to Lambda failures. Periodically remove, check and replace.

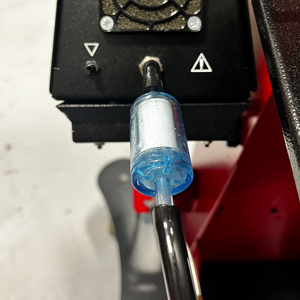

Primary line filter – Can degrade performance if allowed to get blocked

Particulate Filter Element (Top Filter):

Periodically remove, check and replace. Avoids degradation of system performance. To access, remove the water coalescing filter

Water Coalescing Filter Element (Bottom Filter):

Periodically remove, check and replace. Water bowl filters filter from the inside out. Avoids degradation of system performance

Exhaust probe: Should be replaced as needed. Check for damage that could lead to leak check failures

Gas hoses: Check for kinks and damage that could lead to a leak check failure

Safety Precautions:

Before getting started with any maintenance or replacement procedure, ensure that the emissions analyser is turned off. Complete a full Windows shutdown from the workstation software. Then switch off the workstation from the red switch located at the rear of the machine and unplugged from the mains power supply.

Quick Tip: O2 Cell Maintenance

The O2 (oxygen) Cell is a crucial component that measures the oxygen content in the exhaust gas, enabling accurate calculations of emissions levels. The following procedure guides you through the simple procedure of replacing the O2 Sensor on the DGA Series of Emissions Analysers.

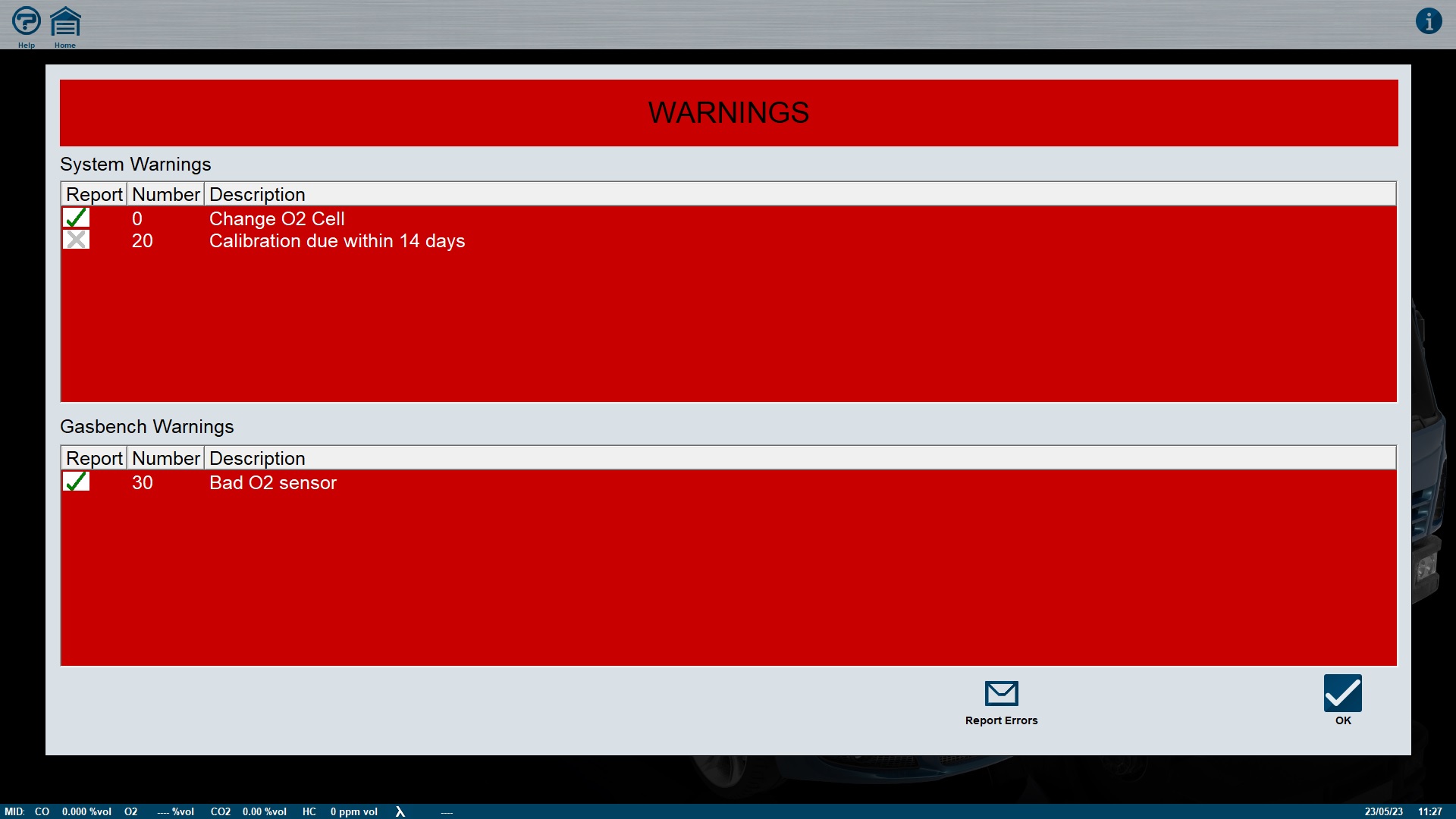

The DGA6000 LINK will provide a system warning when the O2 cell requires replacement, look out for the following warning:

Code 0 – Change O2 Cell. Action required: Replace O2 sensor and calibrate immediately.

Additionally, if you notice any visible damage or irregularities, it is recommended to replace the O2 cell. A replacement O2 sensor can be ordered directly from the Snap-on consumables website here: snaponconsumables.co.uk/product/oxygen-o2-sensor

Replacing the O2 Cell

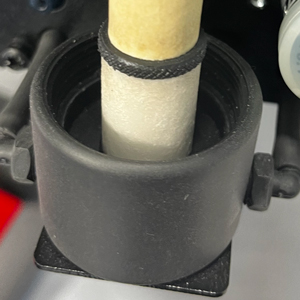

Step 1 Accessing the O2 Cell: Locate the O2 cell on the Sun DGA6000 LINK emissions analyser. This is located on the front of the SGM III module. Simply disconnect the filter cable by pulling away from the filter and then unscrew the filter in an anti-clockwise direction.

Step 2 Checking the O2 Cell: Inspect the O2 cell for any physical damage, such as cracks. Ensure that the cell's connectors and wiring are intact and securely attached. Additionally, inspect the colour of the O2 cell, a dark grey or black colouring within the O2 sensor is a sign that the cell is coming towards the end of its recommended life.

Step 3 O2 Cell Installation: Be sure to inspect the condition of the O2 cell prior to installation. To install the new O2 cell simply repeat step one in reverse. Locate the O2 cell into position and turn in a clockwise direction to secure it. Do not over-tighten the threads. Re-attached the cable to the top of the O2 cell to complete the installation. The system will automatically check the condition of the new cell and store the installation date.

Quick Tip: Cleaning your Emissions Analyser

Cleaning a Sun Vehicle Emissions Analyser is essential to ensure accurate readings and maintain its optimal functionality and prolonged life of your equipment.

Using a soft cloth or microfiber towel to gently wipe the exterior of the analyser, removing any dust or dirt. Be careful not to use any harsh chemicals or abrasive materials that may damage the surface. For the display screen, use a screen cleaning solution or a mixture of distilled water and isopropyl alcohol, applied with a lint-free cloth.

Smoke and gas hoses can become dirty relatively quickly as they come into contact with dirty hands and floors regularly, for best results, use a microfibre towel with a mixture of distilled water and isopropyl alcohol. Avoid using harsh chemicals or abrasive materials that could damage the hose line.

Pay attention to any vents or openings and use compressed air or a small brush to remove any debris.

See More Equipment Focus Content

©2023 Snap-on Incorporated. All rights reserved.